As the world accelerates toward “plastic reduction” and “carbon neutrality,” the disposable tableware industry is undergoing a profound transformation. Manufacturers are shifting away from traditional virgin plastics toward eco-friendly, recyclable raw materials. Among them, rPS pellets (recycled polystyrene) stand out as one of the most practical and sustainable alternatives.

As a professional rPS pellet manufacturer, we are dedicated to supplying high-quality, consistent recycled PS raw materials that help injection molding factories reduce costs, maintain product performance, and achieve true green production.

What Are rPS Pellets and Why Are They the Future of Plastic Manufacturing?

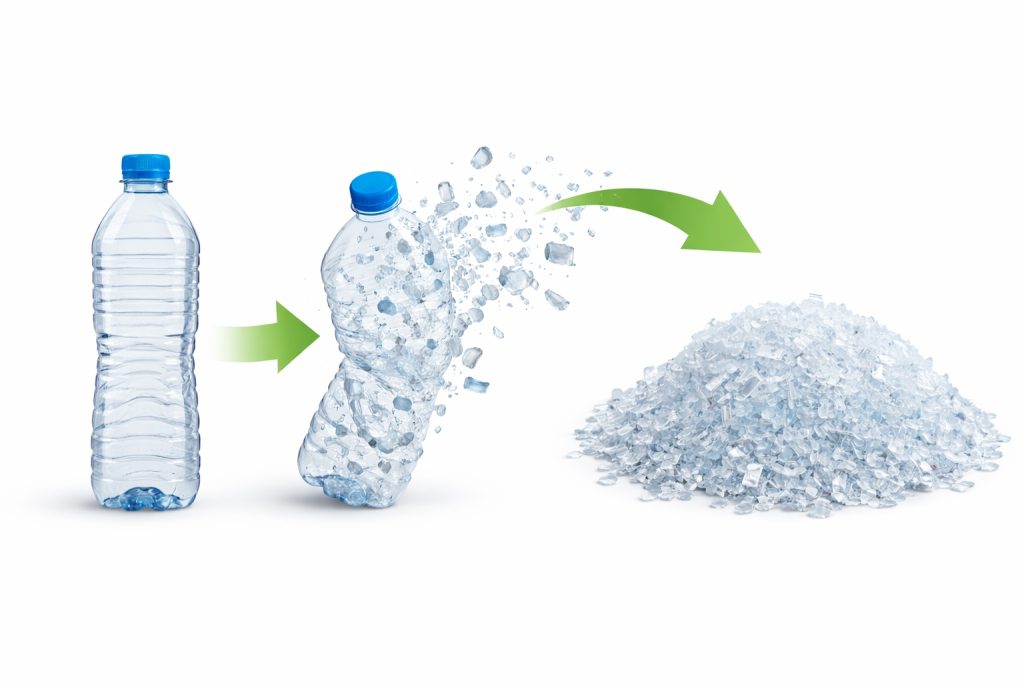

rPS pellets are produced by recycling, cleaning, sorting, and re-pelletizing post-consumer or post-industrial polystyrene (PS) waste. Compared with virgin PS, the production of rPS requires far less energy and generates up to 60% fewer carbon emissions, making it a key material for a low-carbon and circular economy.

From a performance standpoint, rPS pellets offer excellent flowability, heat resistance, and mechanical strength, perfectly suited for multi-cavity, high-speed injection molding. They deliver a smooth surface finish, high whiteness, and — when properly modified — can nearly match the performance of virgin PS pellets.

For manufacturers of disposable injection molded products, rPS offers a powerful combination of eco-compliance and economic advantage.

Broad Applications of rPS Pellets in Injection Molded Disposable Tableware

rPS pellets are now widely used in the production of disposable cutlery, including forks, knives, spoons, plates, bowls, takeaway containers, beverage cups, and lids.

Thanks to their superior melt flow and cooling characteristics, rPS enables fast injection cycles and stable mold performance, resulting in improved productivity. Finished products have a glossy appearance, firm texture, and consistent dimensional accuracy — meeting both food safety and aesthetic requirements.

For transparent or colored items, rPS pellets can be easily combined with PS-based masterbatches, allowing for flexible color adjustment without compromising mechanical strength. With proper formulation and melt index selection, rPS can be tailored for various product thicknesses and design demands.

Why More Injection Molding Companies Are Switching to rPS

The adoption of rPS pellets is not only an environmental choice — it’s a smart business decision.

First, rPS offers significant cost savings. It is typically 15–25% cheaper than virgin PS, helping manufacturers remain competitive while maintaining product quality.

Second, using recycled PS helps companies meet sustainability and regulatory requirements in export markets. rPS materials can support certifications such as GRS (Global Recycled Standard) and ISO 14001, enhancing brand reputation and compliance.

Third, rPS is highly customizable. We offer rPS pellets with different melt flow indices, whiteness levels, colors, and impact resistance grades to suit each customer’s injection process and product specifications — ensuring consistent results even on high-speed production lines.

Technical Guidelines for Injection Molding with rPS

For optimal performance, we recommend an injection temperature range of 180°C to 240°C, depending on product thickness and melt flow rate. Molds should be well-ventilated to prevent air streaks or silver marks.

In high-humidity environments, pre-drying at 80°C for 2 hours is advised to eliminate moisture and improve product surface quality. When coloring, rPS pellets work best with PS-based color masterbatches to ensure even pigment dispersion.

Our technical team provides on-site or remote process optimization support, helping customers improve yield rates, reduce production defects, and maximize efficiency.

Advanced Production and Strict Quality Control

As a specialized rPS pellet producer, we maintain strict control at every production stage to ensure purity, consistency, and performance.

We carefully select high-quality PS scrap sources to minimize impurities. Multi-stage degassing and filtration systems remove contaminants and ensure clean, uniform pellets. Optical sorting equipment guarantees consistent color and brightness across batches.

Every batch of rPS pellets undergoes melt flow index, density, ash content, and impact strength testing, ensuring stable, traceable performance. Our quality management system allows customers to use rPS pellets directly on existing PS injection lines without equipment modification.

Proven Success and Customer Feedback

Our rPS pellets are currently exported to Southeast Asia, Latin America, and Europe, serving a wide range of disposable tableware manufacturers.

Customers report that using our rPS pellets results in:

-

Smoother surface finish and brighter appearance

-

Consistent injection cycles and shorter cooling times

-

Easier certification under environmental standards

-

Noticeable reduction in raw material costs

Many long-term partners have successfully transitioned from virgin PS to 100% recycled PS, achieving both sustainability and profitability goals.

Toward a Sustainable Future in Plastic Tableware Manufacturing

The future of the injection molded tableware industry will be defined by recyclable materials, low-carbon production, and traceable supply chains. rPS pellets — with their balance of performance, sustainability, and cost-effectiveness — are at the heart of this transformation.

As a trusted rPS pellet manufacturer, we will continue innovating in recycled PS processing, improving purity and performance, and supporting customers worldwide in achieving sustainable, circular manufacturing.

Choosing rPS pellets means choosing a cleaner, smarter, and more competitive future.

✅ Contact Us

If you are a disposable tableware manufacturer seeking high-quality, stable recycled PS pellets for injection molding, we welcome you to contact us.

We provide:

-

Free sample testing

-

Customized formulations

-

Technical process support

-

Long-term raw material supply