Introduction

The recycling and reuse of PET (Polyethylene Terephthalate) bottles have become an essential process in today’s efforts to reduce plastic waste and promote sustainability. PET bottles, widely used in packaging, especially for beverages, pose a significant environmental challenge when disposed of improperly. Recycling PET bottles into clean flakes, granules, and sheets not only minimizes waste but also reduces the reliance on virgin plastic, contributing to a more sustainable and eco-friendly future. This process enables businesses to take a more active role in fulfilling their corporate social responsibility, while also complying with environmental regulations that increasingly mandate the use of recycled materials.

Recycling PET is also beneficial for industries that aim to reduce their carbon footprint, conserve valuable resources, and ensure the longevity of materials. By transforming waste PET bottles into reusable products, we contribute to the circular economy, turning waste into valuable resources.

The Source of Recycled PET: From Consumer Bottles to Clean Flakes

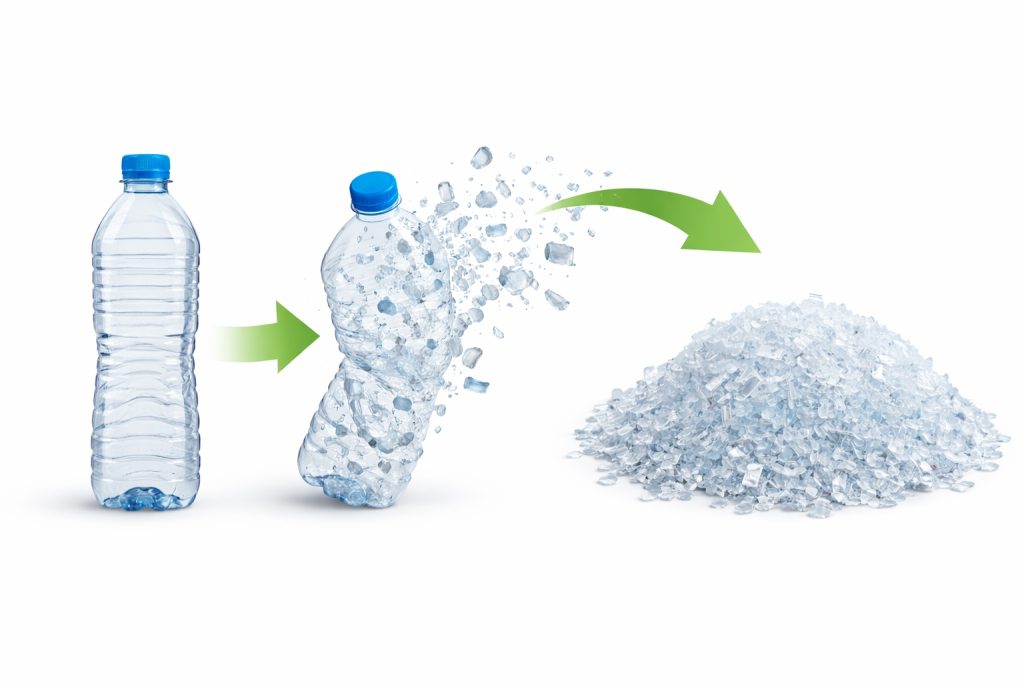

The journey of recycling PET begins with the collection of post-consumer bottles—empty containers that have been discarded by consumers. These bottles are the main source material for the entire recycling process. Initially, the bottles are sorted to remove any non-PET materials, such as PVC or glass, ensuring that only PET materials proceed to the next stage.

Bottles to Flakes: Once sorted, the PET bottles are shredded into small pieces, commonly referred to as PET flakes. This is the first step in breaking down the plastic into smaller, more manageable parts. The PET flakes are small, lightweight, and ready for further processing.

Cleaning Process: After the bottles are shredded, the next crucial step is to clean the PET flakes. This process involves washing the flakes in water with detergents to remove contaminants such as labels, inks, and any residual contents. The cleaning ensures that the PET flakes are free from impurities, which is essential for producing high-quality recycled products. Once cleaned, the flakes are dried and prepared for further transformation.

The Versatility of Clean PET Flakes: Applications Across Industries

Once the PET flakes are cleaned and ready, they can be used in a variety of applications. Clean PET flakes are a versatile material, and their uses span multiple industries. Here are some of the most common applications:

Production of Granules: Clean PET flakes are often processed into recycled PET granules, which serve as the raw material for manufacturing new plastic products. These granules can be used in the production of bottles, containers, and packaging materials. They are ideal for creating products with similar strength, durability, and flexibility as virgin PET.

Sheets for Packaging: PET flakes can also be transformed into sheets, which are commonly used in packaging applications, such as blister packs, clamshell packaging, and food containers. PET sheets provide a high level of transparency, strength, and barrier properties, making them ideal for protecting products while maintaining their visibility.

Strapping Materials: Recycled PET flakes can be further processed into strapping materials, which are used for securing cargo, packaging, and bundling products. These materials provide high tensile strength and are a sustainable alternative to traditional strapping materials.

The versatility of clean PET flakes highlights their value as a sustainable resource that can be repurposed for a wide range of products.

The Process of PET Granulation: Making Recycled PET More Eco-Friendly

The next step after cleaning the PET flakes is the granulation process, where the flakes are heated and melted to create recycled PET granules. Granulation involves melting the clean flakes and extruding them into small, uniform pellets, which are then cooled and cut to size. These recycled PET granules are highly versatile and can be used in various manufacturing processes.

Eco-Friendly Advantage: Recycled PET granules are significantly more environmentally friendly than virgin PET. By using recycled PET, manufacturers reduce the need for petroleum-based materials, lower energy consumption, and decrease carbon emissions. This process also helps reduce plastic waste, contributing to a more sustainable future.

Meeting Global Sustainability Goals: With increasing global demand for eco-friendly products, the use of recycled PET granules is becoming more widespread. These granules are used in a variety of products, from consumer goods to automotive parts and packaging. By utilizing recycled PET, businesses can meet their sustainability goals, reduce their environmental impact, and comply with stricter regulations on plastic usage.

Applications of Recycled PET Granules: Food-Grade and Fiber-Grade

Recycled PET granules come in two main grades, each with specific applications:

Food-Grade Recycled PET: This grade of recycled PET granules is used in the production of food packaging materials, including new bottles and containers for beverages, dairy products, and other food items. Food-grade recycled PET meets strict safety and quality standards to ensure it is safe for food contact.

Fiber-Grade Recycled PET: Fiber-grade recycled PET is used primarily in the textile industry to produce products such as clothing, carpets, upholstery fabrics, and other textiles. Recycled PET fibers are a sustainable alternative to virgin polyester and contribute to the growing trend of eco-friendly fashion.

Both grades of recycled PET granules help reduce waste and offer sustainable solutions for industries that rely on plastic materials.

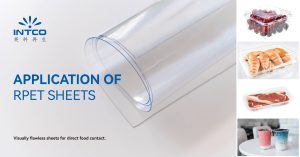

The Production Process of PET Sheets and Their Applications

In addition to granules, PET flakes can also be processed into sheets through extrusion. During extrusion, the cleaned and melted PET flakes are formed into large, flat sheets, which are then cooled and cut to the desired thickness.

PET sheets are highly versatile and can be used in a wide range of applications:

Packaging: PET sheets are commonly used in blister packs, clamshell packaging, and food containers. These sheets provide excellent strength, durability, and transparency, making them ideal for protecting products while maintaining their visual appeal.

Display and Signage: Transparent PET sheets are also used for displays, signage, and protective covers. Their clarity and durability make them suitable for use in retail environments and as protective covers for various materials.

Recycled PET sheets provide a sustainable and high-performance alternative to traditional materials, helping industries meet their environmental goals.

INTCO —— Stable Supply and High Quality

INTCO offers a wide range of recycled PET products, including pellets, flakes, and sheets, all sourced from post-consumer PET bottles. With an annual production capacity of 50,000 tons, INTCO ensures a stable supply of high-quality materials, making it a trusted partner for industries across the globe.

Our recycled PET products are made with a focus on sustainability, quality, and performance, meeting the needs of various applications, from packaging to textiles. Whether you need food-grade pellets, fiber-grade granules, or PET sheets for packaging, INTCO can supply you with the materials you need.

Contact us today to learn more about our recycled PET solutions and how we can support your business’s sustainability goals.