Recycled PS (RPS) Pellets in XPS Insulation Boards: Applications & Benefits

Discover the applications of recycled polystyrene (RPS) pellets in XPS insulation boards, including performance benefits, manufacturing process, and environmental value for sustainable building materials.

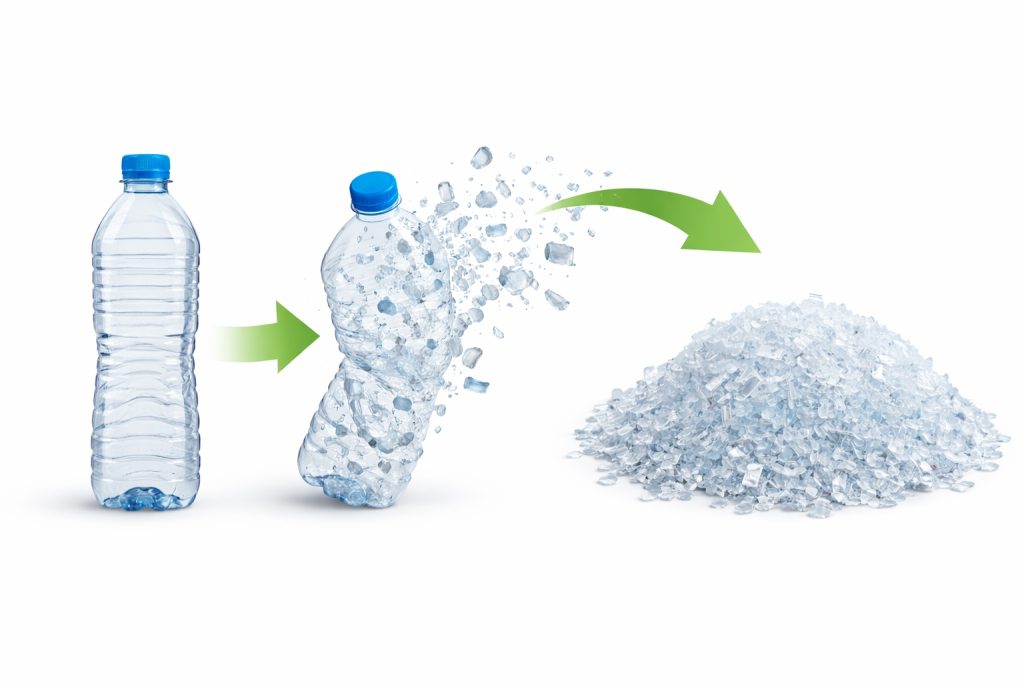

What Are Recycled PS (RPS) Pellets?

Recycled PS (RPS) pellets are granules made from post-consumer or post-industrial polystyrene waste. In XPS (extruded polystyrene) insulation board production, RPS pellets can partially replace virgin material, enabling material recycling, reducing costs, and maintaining excellent thermal insulation properties.

Key Features:

-

Uniform pellet size suitable for high-temperature extrusion

-

Can effectively participate in foam formation, ensuring stable board structure

-

Environmentally friendly and recyclable

Simply put, RPS gives a “second life” to waste PS, adding green value to XPS insulation boards.

Advantages of RPS in XPS Insulation Boards

Environmental Sustainability

-

Reduces plastic waste in landfills

-

Lowers dependency on petroleum-based raw materials

-

Supports green and energy-efficient building initiatives

Excellent Thermal Insulation

-

Properly processed RPS maintains a low thermal conductivity

-

Comparable thermal resistance to conventional XPS boards

-

High-density foam ensures long-term insulation performance

Cost Reduction

-

Waste PS is cheaper than virgin polystyrene

-

Partial replacement lowers overall material costs

-

Improves raw material utilization and reduces waste

Ease of Processing

-

RPS pellets are compatible with extrusion foam processes

-

Flexible mixing ratio with virgin material

-

Does not compromise board compressive strength or appearance

Applications of RPS XPS Insulation Boards

-

Exterior Wall Insulation: Environmentally friendly thermal solution

-

Roof Insulation: Reduces heat loss, improves energy efficiency

-

Basement & Moisture Protection: Dense foam limits vapor penetration

-

Cold Storage & Refrigeration: Maintains stable low-temperature environments

Using RPS in XPS boards not only enhances sustainability but also meets high-performance insulation needs.

How to Choose High-Quality RPS XPS Boards

- Check Pellet Quality: Uniform and free of impurities

- Verify Board Density and Thermal Conductivity: Higher density means better insulation

- Certification Standards: ASTM, EN, or GB compliance

- Reliable Suppliers: Experienced manufacturers ensure stable product quality

Installation and Maintenance Tips for RPS XPS Boards

-

Before Installation: Ensure boards are dry and flat

-

During Installation: Avoid moisture exposure or excessive stress

-

Maintenance: Inspect the surface for damage and keep waterproof layers intact

Conclusion and Call-to-Action

Recycled PS (RPS) pellets in XPS insulation boards exemplify the combination of environmental responsibility and high performance. By selecting the right RPS ratio and quality suppliers, XPS boards can reduce costs while supporting green building goals.

Want to learn more about RPS or get a quote? Contact our experts today for sustainable solutions for your project!