Introduction to rPS Pellets and Their Material Characteristics

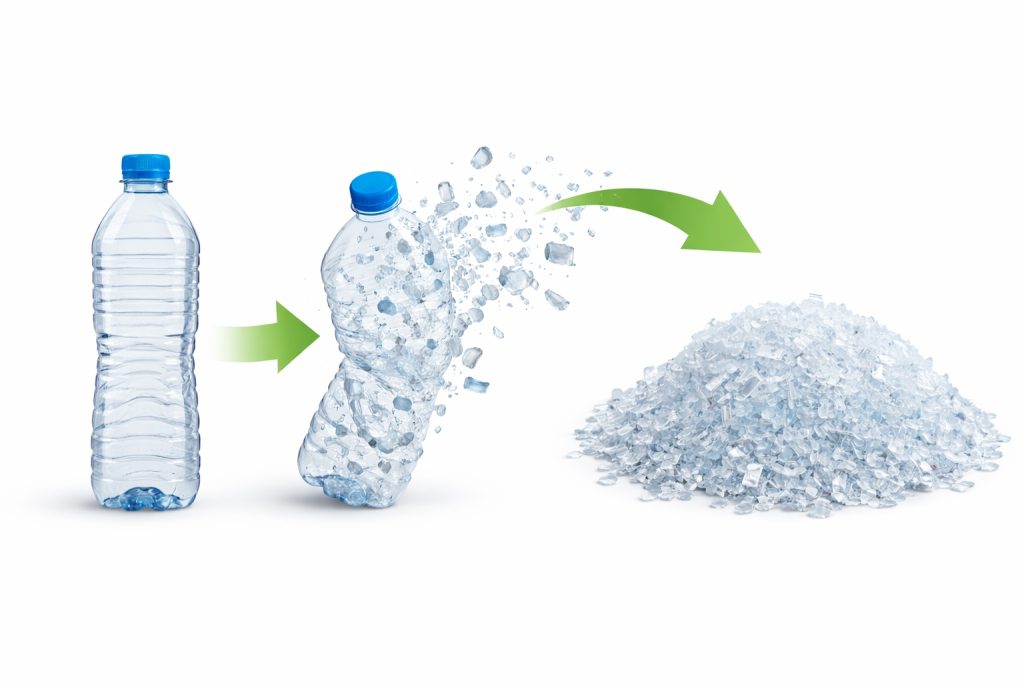

rPS pellets (Recycled Polystyrene Pellets) are produced from post-consumer or post-industrial polystyrene waste through processes such as sorting, washing, melting, filtering, and re-granulation. They retain the essential molecular structure and physical properties of virgin polystyrene (PS), while offering significant sustainability and cost benefits.

As a thermoplastic polymer, rPS has several inherent characteristics:

Stable molecular structure: Linear polymer chains provide rigidity and dimensional stability.

Excellent processability: Good melt flow and thermal behavior make it suitable for extrusion, foaming, and thermoforming.

Chemical resistance: Low water absorption and resistance to acids and bases, suitable for food-contact applications.

Recyclability: Can be reprocessed multiple times without major performance loss.

These properties make rPS pellets an ideal material for use in foam products, particularly in the manufacturing of disposable foam food containers.

Production and Quality Control of rPS Pellets

The consistency and quality of rPS depend largely on the purity of the raw materials and the precision of the production process. High-quality rPS is typically derived from single-type PS waste—such as packaging foam or food trays—that has been thoroughly cleaned and purified.

Key stages of the production process include:

Sorting and material selection: Ensuring no PVC, ABS, or mixed plastics contamination.

Cleaning and impurity removal: High-temperature washing and multi-stage filtration to eliminate residues and colorants.

Melt homogenization: Twin-screw extrusion for uniform molecular distribution and stable flow characteristics.

Performance testing: Measuring melt flow index, ash content, impurities, odor, and color to ensure consistency.

Strict process control guarantees that each batch of rPS pellets exhibits reliable performance during downstream foaming and molding operations.

Application Mechanism of rPS in Foam Food Containers

Foam food containers are generally made from expandable or extruded polystyrene (EPS/XPS) through a process of heating, foaming, and thermoforming. Because rPS shares the same polymer backbone as virgin PS, it can be incorporated into these processes with minimal equipment modification.

During foaming, rPS interacts with the blowing agent (e.g., butane or CO₂) to form a stable microcellular structure. High-quality rPS provides:

Uniform cell distribution, ensuring consistent density and surface finish;

Appropriate melt strength, maintaining dimensional stability during forming;

Good sealing and mechanical properties, meeting the requirements for insulation, rigidity, and food safety.

By adjusting the blending ratio between rPS and virgin PS, manufacturers can achieve an optimal balance between cost and performance.

Environmental and Economic Significance of rPS Application

Reduction of raw material consumption and carbon footprint Using rPS decreases the demand for fossil-based virgin PS and lowers the overall energy consumption and CO₂ emissions in production.

Promotion of circular plastic economy The integration of rPS into foam packaging provides an effective end-use pathway for polystyrene waste, closing the recycling loop.

Compliance with sustainability regulations Many countries are introducing recycled-content requirements for plastic packaging. rPS helps manufacturers meet these standards and enhance their environmental reputation.

Economic feasibility rPS offers a more cost-effective alternative to virgin PS while maintaining similar performance, making it suitable for large-scale, sustainable production.

Future Development Trends

With ongoing advancements in recycling and compounding technology, rPS pellets continue to evolve in quality and application potential. The main directions of development include:

Food-grade rPS: Improved deodorization and purification for food-contact compliance.

High-foaming rPS: Optimized molecular weight distribution to achieve higher expansion ratios and lighter density.

Functional modification: Blending with impact modifiers or additives to enhance toughness, heat resistance, and oxidation stability.

Digital traceability: Implementation of labeling and data systems for full material traceability within the recycling chain.

These innovations will expand rPS usage across a broader range of foam packaging and consumer product applications.

Conclusion

rPS pellets represent a sustainable, efficient, and economically viable solution for the foam packaging industry. In foam food container production, rPS not only maintains material performance but also aligns with global goals of resource conservation and environmental responsibility.

As circular economy practices deepen, rPS will continue to play a vital role in driving the transformation of foam product manufacturing toward a greener and more sustainable future.