Introduction to PET Materials in Healthcare

Polyethylene Terephthalate (PET) has become one of the most important materials in modern pharmaceutical and medical packaging. Known for its high clarity, excellent strength, and outstanding barrier properties, PET materials are widely used for packaging liquid medicines, tablets, diagnostic tools, sterile medical devices, and laboratory products. As the healthcare sector shifts toward safer, more sustainable and cost-effective materials, PET packaging continues to gain popularity due to its reliability, purity, and compliance with international pharmaceutical standards.

Key Material Properties That Make PET Ideal for Pharmaceutical and Medical Use

High Clarity and Transparency

One of the primary advantages of PET is its high transparency, which allows clear visibility of the product inside. For pharmaceutical companies, this is crucial for proper identification, quality control, and patient confidence. PET offers glass-like clarity without the risk of shattering.

Excellent Barrier Properties

PET provides strong moisture, oxygen, and chemical barriers, ensuring long-term stability of sensitive drug formulations. Many liquid medicines, vitamin solutions, and oral suspensions rely on PET bottles to prevent contamination and maintain efficacy during storage and transport.

Chemical Resistance and Purity

Medical-grade PET is known for its chemical inertness. It does not react with most liquid drugs, alcohol-based formulations, or active pharmaceutical ingredients (APIs). This makes PET a reliable choice for pharmaceutical containers, reagents, and diagnostic products where material purity is essential.

Lightweight and Impact Resistant

Compared to glass containers, PET bottles and PET jars are lightweight, easy to transport, and resistant to breakage. This significantly reduces shipping costs and improves handling safety for hospitals, pharmacies, and logistics operators.

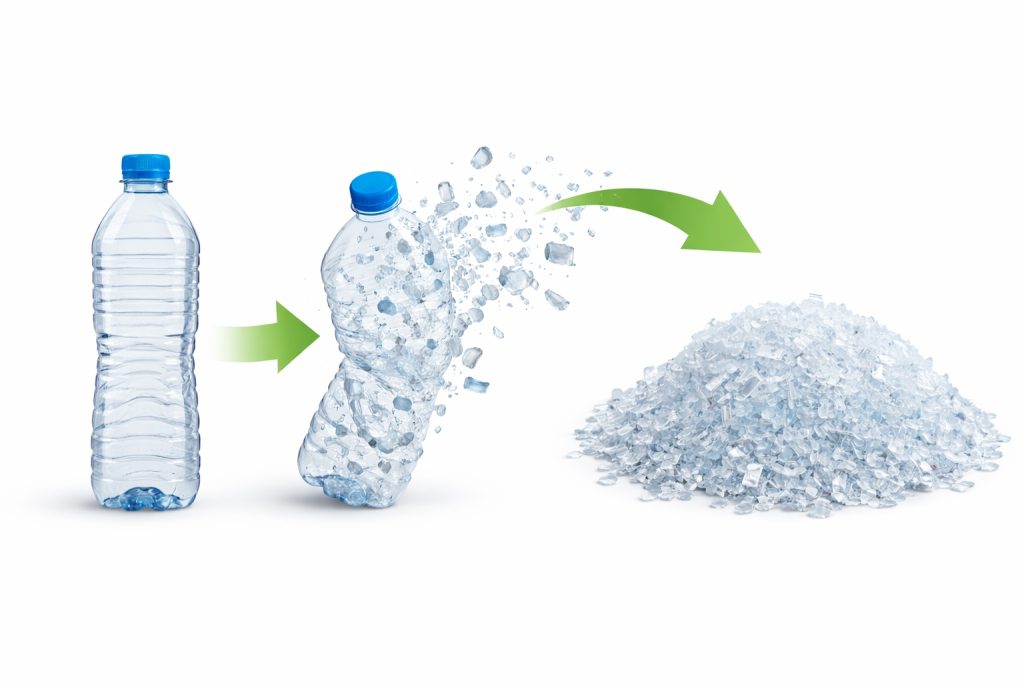

Recyclability and Sustainability

As sustainability becomes a priority, PET stands out for its recyclability. Pharmaceutical companies increasingly adopt PET packaging as part of their ESG commitments and eco-friendly product strategies.

Pharmaceutical Applications of PET Materials

PET Bottles for Liquid Medicines

PET bottles are widely used for cough syrups, oral solutions, ophthalmic fluids, and antiseptic liquids. They offer excellent product visibility, chemical resistance, and drop protection—making them a safer alternative to glass.

PET Containers for Tablets and Capsules

Solid oral dosage forms such as tablets, capsules, and supplements are often packaged in PET jars or amber PET bottles. These provide a moisture barrier to preserve product potency while offering lightweight convenience for consumers.

PET Blister Packaging and Medical Films

Multilayer PET films are increasingly used in blister packaging for tablets and soft gels. PET’s durability and clarity make it suitable for medical pouches, sterilizable films, and lidding materials.

Laboratory and Diagnostic Containers

PET is also widely used in laboratory sample bottles, reagent containers, test vials, and other diagnostic tools. Its purity and resistance to contamination ensure high accuracy in medical testing environments.

Medical Applications of PET Materials

PET for Medical Device Packaging

PET and PETG sheets are commonly used in thermoformed medical trays, sterile barrier systems, and packaging for surgical instruments. These materials are compatible with sterilization methods such as gamma irradiation and EtO sterilization.

PET Sheets and Films for Sterile Barriers

Medical-grade PET films provide reliable sealing and protection for disposable medical tools, syringes, and surgical kits. PET’s durability prevents puncturing or tearing during transport.

PET in IV and Healthcare Consumables

Some medical consumables, such as fluid containers, filtration components, and oxygen mask parts, are made from PET or modified PET due to its clarity and resistance to impact.

PET for Imaging and Diagnostic Equipment

Although unrelated to PET-CT scans (where PET means “Positron Emission Tomography”), PET materials are used structurally in some diagnostic tools, X-ray accessories, and housings requiring lightweight yet durable components.

Regulatory Considerations and Quality Standards

In the pharmaceutical and medical fields, compliance is essential. PET materials used for drug and device packaging must meet rigorous global standards, including:

-

USP Class VI for medical-grade plastics

-

FDA regulations (21 CFR) for safe food and drug contact

-

EU Pharmacopeia standards

-

ISO certifications for sterile packaging materials

Manufacturers must ensure that PET packaging is free from contaminants, heavy metals, and additives that may interact with medical products.

Market Trends and the Future of PET in Healthcare

The global demand for PET in pharmaceutical and medical applications continues to rise due to:

-

The shift from glass to lightweight plastic

-

Growing demand for sustainable packaging solutions

-

Increased use of PET films for sterile barrier packaging

-

Advancements in medical-grade PET and high-purity PET resins

-

The development of recyclable PET (rPET) and its future potential in healthcare

As healthcare companies search for safer, more efficient packaging materials, PET will remain a key player in the medical supply chain.

Conclusion

PET materials offer a powerful combination of clarity, durability, chemical resistance, and sustainability—making them ideal for both pharmaceutical and medical applications. Whether used for medicine bottles, blister packs, sterile device packaging, or diagnostic tools, PET provides a reliable and high-performance solution that meets strict industry standards.

With its strong environmental advantages and expanding role in global healthcare, PET is set to remain an essential material for modern medical and pharmaceutical packaging.