Introduction: Sustainability Driving Change in Electronics Packaging

As global demand for sustainability accelerates, the electronics industry is increasingly seeking environmentally friendly packaging materials. Traditional plastics, while durable, create long-term environmental burdens and require large amounts of fossil resources. In this context, recycled PET (r-PET) is emerging as a leading solution—delivering both high performance and significant environmental benefits. Electronics manufacturers now view r-PET as a viable, responsible, and future-proof alternative.

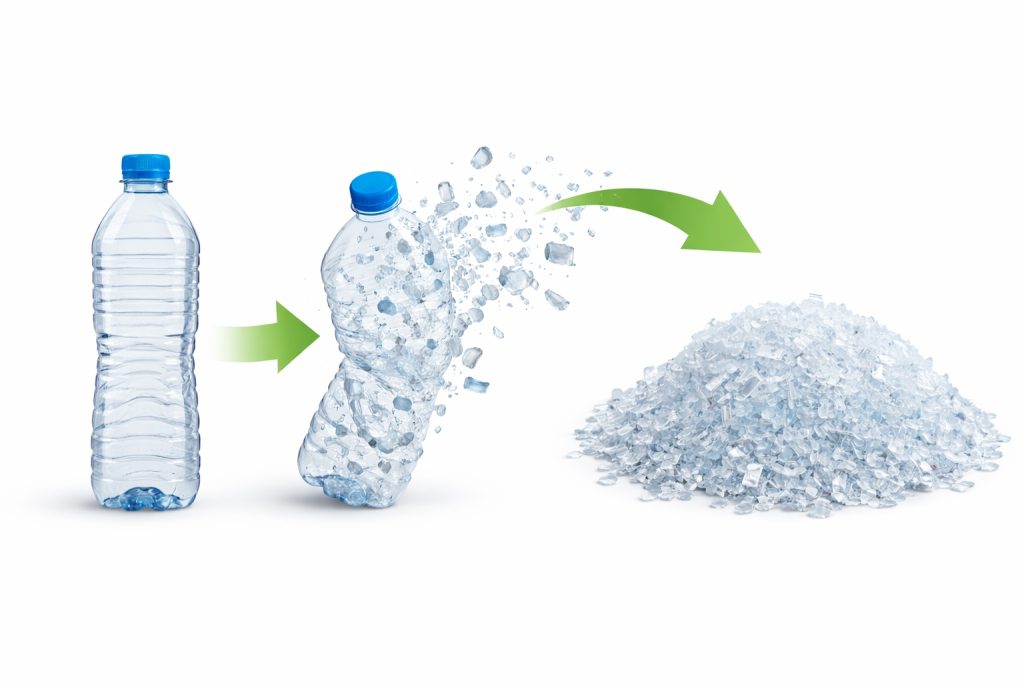

What Is Recycled PET?

Recycled PET (Recycled Polyethylene Terephthalate) is produced from post-consumer materials such as PET bottles, packaging trays, and sheet offcuts. Through advanced processes including sorting, washing, purification, and reprocessing, these materials are converted into high-quality r-PET sheets, flakes, or pellets.

Key properties that make r-PET ideal for electronics packaging include:

-

Excellent clarity

-

Strong mechanical strength

-

Good heat and chemical resistance

-

Dimensional stability

-

Suitability for thermoforming and molding

Advantages of Recycled PET for Electronics Packaging

3.1 High Mechanical Strength and Protection

Electronic components are delicate and require packaging that provides superior impact resistance. r-PET offers excellent mechanical durability, ensuring safe storage and transportation.

3.2 Excellent Clarity for Display Packaging

Many consumer electronics—such as headphones, cables, chargers, and accessories—require transparent blister packaging. r-PET delivers high clarity and premium appearance while maintaining strength.

3.3 Heat and Chemical Resistance

During shipping or storage, electronics may be exposed to temperature variations or chemicals. r-PET maintains its integrity under these conditions better than many other recycled plastics.

3.4 Dimensional Stability and Precision

r-PET retains its shape and provides stable support for precision parts, essential for fragile items like circuit boards, hard drives, and microcomponents.

3.5 Lightweight and Easy to Process

r-PET sheets thermoform smoothly, enabling efficient production of blisters, clamshells, and trays with excellent detail reproduction.

Environmental and Sustainability Benefits

Choosing recycled PET helps electronics brands significantly reduce their environmental impact:

-

Lower carbon emissions compared to virgin PET

-

Reduced energy consumption in production

-

Less plastic waste entering landfills and oceans

-

Supports global circular economy goals

-

Helps meet ESG, brand, and regulatory requirements

As sustainability becomes a market expectation, r-PET packaging provides a key competitive advantage.

Main Applications of Recycled PET in Electronics Packaging

Recycled PET’s versatility makes it ideal for a wide range of packaging formats in the electronics sector:

-

Thermoformed blisters and clamshells for retail packaging

-

Anti-static or conductive r-PET trays for sensitive electronic parts

-

Protective cushioning sheets for logistics

-

Packaging for mobile accessories like earphones, power banks, chargers

-

Component trays used in assembly lines and clean rooms

These applications demonstrate r-PET’s blend of durability, clarity, processability, and eco-friendliness.

Why Electronics Manufacturers Prefer r-PET

Electronics companies are rapidly adopting r-PET because it offers:

-

Stable supply availability

-

High purity and consistency

-

Strong price competitiveness vs. virgin PET

-

Customizable functional properties, such as:

-

Anti-static additives

-

Conductive agents

-

Scratch-resistant coatings

-

Color customization

-

This adaptability makes r-PET suitable for both premium retail packaging and industrial protective systems.

Industry Trends and Future Outlook

The use of recycled PET in electronics packaging will continue to grow due to:

-

Increasing regulatory pressure requiring higher recycled content

-

Rising consumer demand for sustainable electronics

-

Innovations in PET recycling technology improving quality

-

Expansion of circular supply chains across global electronics brands

r-PET is poised to become a standard material for sustainable packaging solutions.

Conclusion: r-PET as the Future of Electronics Packaging

Recycled PET combines excellent protective performance with significant environmental benefits, making it an ideal choice for electronics packaging. As the electronics industry continues moving toward greener, more responsible practices, r-PET provides a scalable, durable, and high-quality material that supports both sustainability goals and market demands.

Electronics manufacturers who adopt r-PET today will be better positioned to meet future environmental regulations, reduce carbon footprints, and enhance brand value in a sustainability-driven world.