Introduction

Sustainability has become a core focus in the short fiber industry, which includes textiles, automotive applications, and insulation materials. Recycled PET (Polyethylene Terephthalate) has emerged as a key material in driving eco-friendly practices while maintaining performance standards. This article explores how recycled PET is transforming the short fiber industry by offering sustainable solutions and improving product performance.

What is Recycled PET?

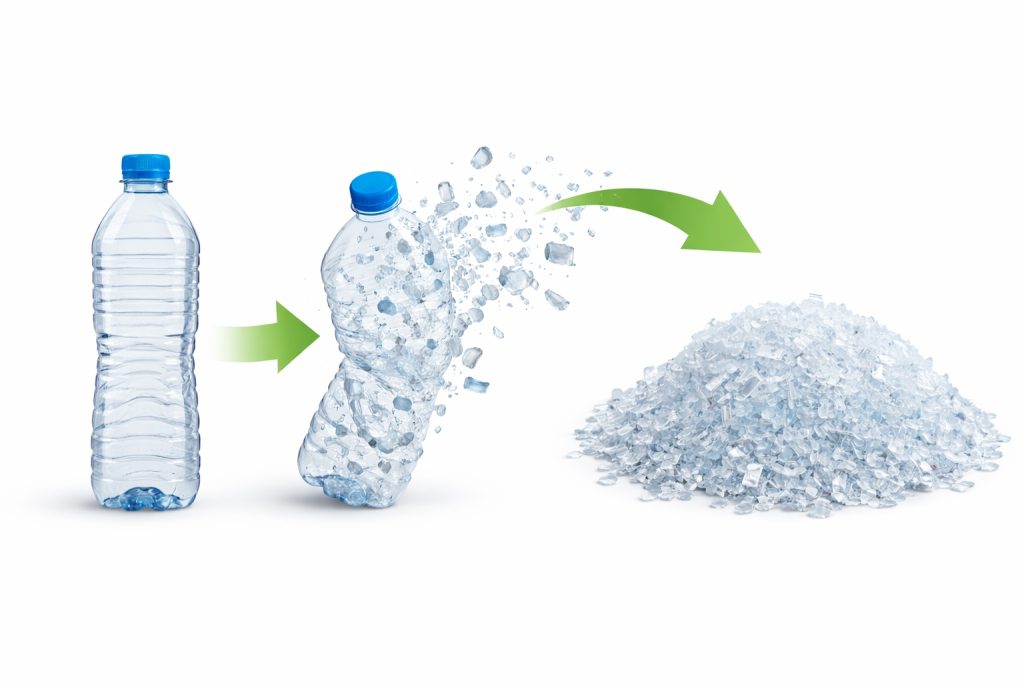

Recycled PET is derived from post-consumer plastic waste, typically bottles and containers, which is then processed into new fibers or pellets for reuse. This recycling process conserves natural resources and reduces energy consumption compared to the production of virgin PET. By using recycled PET, manufacturers can help minimize plastic waste and contribute to a circular economy.

Importance of Sustainability in the Short Fiber Industry

The short fiber industry, traditionally reliant on synthetic fibers derived from petroleum, has faced increasing pressure to adopt more sustainable practices. As consumers demand more eco-friendly products, using recycled PET offers a viable solution to meet these demands. It helps reduce the environmental impact by lowering carbon emissions, reducing plastic waste, and conserving non-renewable resources.

Applications of Recycled PET in the Short Fiber Industry

Recycled PET has various applications across multiple sectors within the short fiber industry:

-

Textiles and Fabrics: Recycled PET is used to produce sustainable fabrics for apparel and home textiles. These fabrics offer the same quality and durability as virgin PET but with a smaller environmental footprint.

-

Nonwoven Fabrics: In industries such as automotive and hygiene, recycled PET is used to create nonwoven fabrics for car interiors, medical products, and industrial applications. These materials are cost-effective and environmentally friendly.

-

Insulation Materials: Recycled PET fibers are increasingly used in thermal and acoustic insulation products for construction and home improvement, offering both energy efficiency and noise reduction.

-

Packaging: Recycled PET is widely used in packaging, especially in food and beverage containers. Using recycled materials reduces the need for virgin plastic, contributing to sustainability in packaging solutions.

Benefits of Using Recycled PET in Short Fiber Production

The integration of recycled PET into short fiber production brings several advantages:

Environmental Benefits

The most obvious benefit is the reduction of plastic waste. By recycling PET, manufacturers reduce landfill contributions and decrease the overall carbon footprint of production. Additionally, recycled PET requires less energy to produce compared to virgin PET, making it a more sustainable option.

Performance Enhancements

Despite being recycled, recycled PET retains many of the performance characteristics of virgin PET, including strength, durability, and resistance to wear. This makes it an ideal choice for a variety of short fiber applications, from textiles to insulation materials.

Economic Advantages

The use of recycled PET can help reduce material costs for manufacturers, as recycled plastic is often less expensive than virgin PET. Furthermore, the growing demand for sustainable products has created new market opportunities for businesses that adopt recycled PET in their production processes.

Challenges in Adopting Recycled PET

While the benefits are clear, there are some challenges that come with using recycled PET in short fiber applications:

Quality and Purity Concerns

The recycling process can sometimes introduce contaminants that affect the quality of the final product. These impurities can lower the strength and appearance of fibers, especially if the recycling process is not optimized.

Supply Chain Limitations

The availability of high-quality recycled PET can vary by region, depending on local recycling infrastructure and waste management practices. Reliable and consistent sourcing is essential for manufacturers looking to incorporate recycled PET into their production lines.

Technological Barriers

The technology used to process recycled PET is still evolving. Some applications may require high-performance fibers, which may not always be achievable with the current state of recycling technology. Ongoing innovation is necessary to overcome these limitations.

Future Trends and Innovations in Recycled PET

The future of recycled PET in the short fiber industry looks promising, with several trends shaping its growth:

Advancements in Recycling Technology

New recycling technologies are being developed to improve the quality and efficiency of recycled PET production. These innovations help reduce contamination and improve the material’s properties, making it suitable for a wider range of high-performance applications.

Increased Collaboration and Industry Support

To promote the use of recycled PET, industry players, including manufacturers, recycling companies, and government agencies, are collaborating to improve recycling systems and infrastructure. These initiatives aim to increase the availability and quality of recycled materials.

Regulatory Encouragement

Government regulations are increasingly pushing companies to adopt sustainable practices. Policies that mandate the use of recycled materials in manufacturing are helping accelerate the shift toward recycled PET.

Conclusion

The use of recycled PET in the short fiber industry offers numerous environmental, economic, and performance benefits. As recycling technologies improve and industry collaboration grows, recycled PET will play an increasingly vital role in the industry’s sustainability efforts. Manufacturers that adopt recycled PET will not only reduce their environmental impact but also improve their market position by offering eco-friendly products.