Recycled PET Flakes in Strapping Tape: Strength, Efficiency, and Eco Advantages

Introduction

As global industries move toward sustainability, the demand for eco-friendly packaging materials has grown rapidly. Among these innovations, recycled PET flakes have emerged as a key material for producing strapping tapes that are not only strong and efficient but also environmentally responsible. Derived from post-consumer PET bottles and other recyclable plastics, recycled PET flakes provide a practical solution to reduce plastic waste while maintaining exceptional mechanical performance.

What Are Recycled PET Flakes?

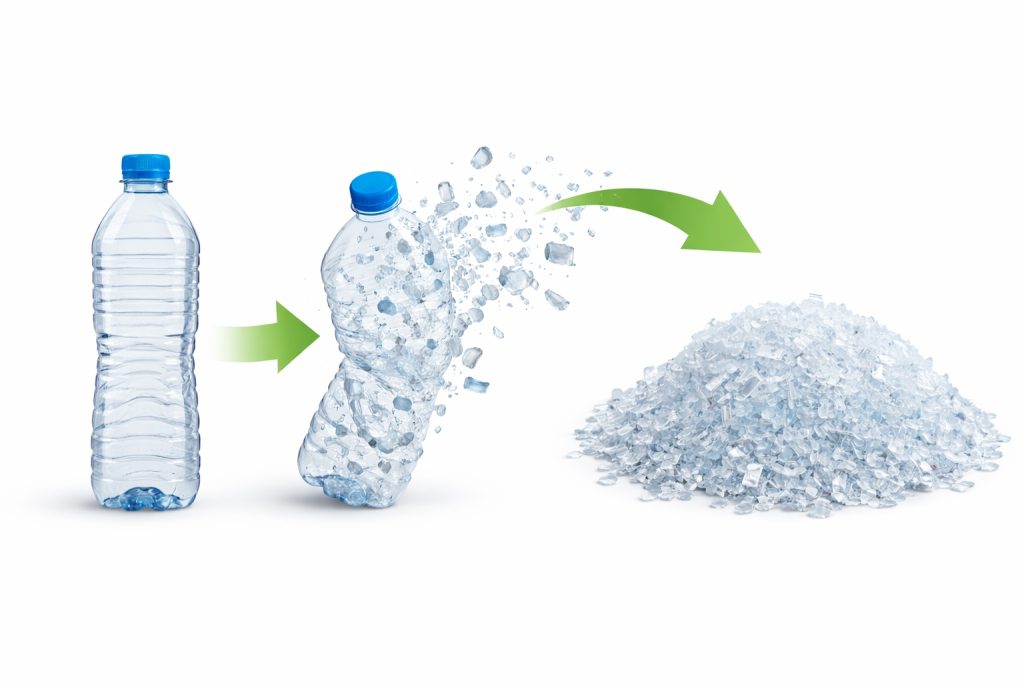

Recycled PET (Polyethylene Terephthalate) flakes are obtained through the mechanical recycling of used plastic bottles and packaging materials. The recycling process involves collection, sorting, washing, shredding, and reprocessing PET waste into clean, high-purity flakes. These flakes are then melted and extruded into new products such as strapping tape, fibers, and sheets.

High-quality recycled PET flakes possess excellent tensile strength, thermal stability, and chemical resistance, making them ideal for industrial applications.

Strength and Durability of Recycled PET in Strapping Tape

One of the most significant advantages of recycled PET flakes is their mechanical strength. PET strapping tapes made from recycled materials offer comparable performance to those produced from virgin PET resin. They maintain high tensile strength, ensuring that heavy loads are securely fastened during transportation and storage.

Recycled PET strapping also exhibits excellent durability under various environmental conditions—resisting moisture, temperature fluctuations, and UV exposure. Through optimized extrusion processes and material blending, recycled PET tapes can achieve consistent performance and dimensional stability, proving that sustainability does not require compromising on quality.

Efficiency in Strapping Tape Production

From a manufacturing perspective, recycled PET flakes offer remarkable efficiency. Because they can be processed using existing production lines, companies can easily integrate recycled raw materials without major equipment modifications.

Moreover, recycled PET is more cost-effective than virgin resin. The recycling process reduces dependence on petroleum-based raw materials, helping stabilize production costs even when crude oil prices fluctuate. A stable supply of recycled PET flakes from global recycling networks also ensures manufacturers can maintain continuous production with predictable input costs.

By combining strong mechanical performance with cost stability, recycled PET strapping tape supports both economic and operational efficiency for packaging manufacturers.

Eco Advantages of Using Recycled PET in Strapping Tape

The environmental benefits of using recycled PET flakes extend far beyond cost savings. By utilizing post-consumer plastics, manufacturers can significantly reduce carbon emissions, energy consumption, and landfill waste. Every ton of recycled PET used prevents approximately 1.5 tons of CO₂ emissions and conserves valuable natural resources.

This process contributes directly to the circular economy, where materials are continuously recovered and reused instead of discarded. In addition, using recycled PET aligns with global sustainability goals such as the EU Green Deal and UN Sustainable Development Goals (SDGs).

As a leading example, INTCO Recycling has established a global recycling network that collects PET waste across more than 100 countries. Through advanced recycling technology, INTCO transforms PET bottles into high-purity recycled flakes, which are then used in strapping tape and other applications. These efforts not only reduce plastic pollution but also help customers achieve measurable sustainability targets in their supply chains.

Real-World Applications and Market Trends

Recycled PET strapping tapes are widely used in logistics, manufacturing, construction, and agriculture. They are ideal for securing heavy cartons, steel coils, bricks, and pallets—offering excellent load stability and safety.

The global market for PET strapping is expected to continue expanding as industries seek green packaging alternatives that balance strength and environmental performance. With governments encouraging recycled content in industrial packaging, demand for recycled PET flakes is projected to rise significantly in the coming years.

Conclusion

The use of recycled PET flakes in strapping tape demonstrates how sustainable materials can deliver outstanding strength, production efficiency, and environmental benefits. By adopting recycled PET, manufacturers not only reduce costs but also take a major step toward achieving their sustainability goals.

As innovation continues and recycling networks expand, recycled PET will play an even greater role in shaping the future of sustainable packaging.

INTCO Recycling remains committed to producing high-purity, certified recycled PET flakes that empower manufacturers worldwide to build a cleaner, more sustainable planet—one strap at a time.